X-ACT

Electroluminescent foils, luminous panels,

EL films, EL strips and inverters

XTRA Dynamics produces EL films of the highest quality. Our luminous films are characterized by high luminance, long service life and a homogeneous luminous image. X-ACT electroluminescent films offer the best visibility even in unfavorable conditions and are protected from extreme weather conditions by a robust protective laminate. even from extreme weather conditions.

Whether in architecture as a 7-segment display, in racing as an illuminated starting number or in the automotive industry as ambient lighting automotive industry as ambient lighting - with little need for installation space: the creative application possibilities of electroluminescent panels are almost limitless. For example combination with fiber-reinforced composites, for example, new new possibilities for colored premium surfaces.

Advantages of our EL foils:

• uniform light

• very thin

• Dimmable as desired

• low power consumption

• can be back-molded

• can be any shape or form

• no heat development

Standard formats

Electroluminescent foils

Standard sizes:

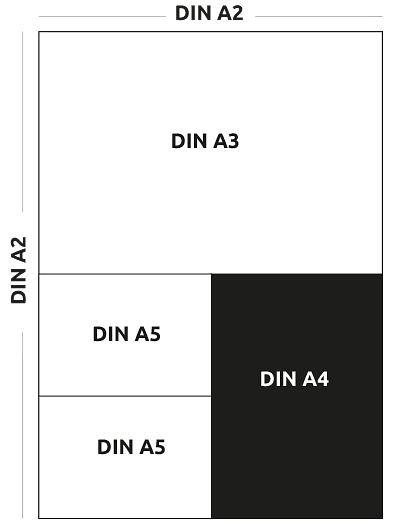

XTRA Dynamics produces X-ACT EL panels in various standard sizes of DIN A2, DIN A3, DIN A4 and DIN A5.

Customized sizes:

EL films can be produced in bespoke sizes and shapes as shown in the images below. Electroluminescent lamps are screen printed and if required we can make screens for our customers. With our laser cutter we can produce your specific EL in any shape, size or form.

Plug and Play EL foils:

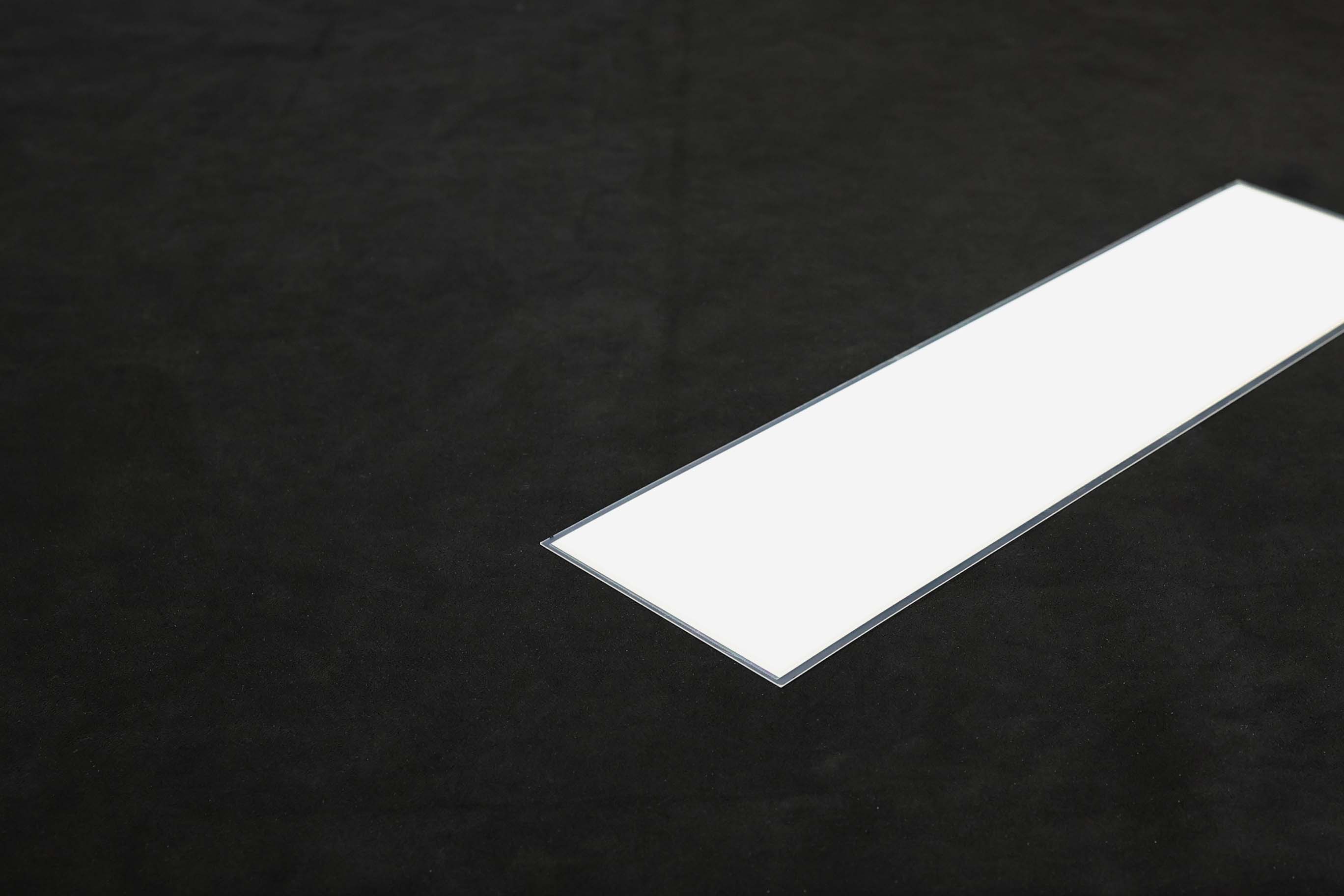

We laminate our EL panels in a variety of protective laminates, from very rigid to elastic PET laminate. Our connections consist of either silver-plated copper strips or gold-plated flex boards. Wires with connectors for our standard inverters are soldered on. This is the most durable solution on the market as it eliminates one of the most common types of failure: bad crimp contacts.

Examples

Illuminated car numbers for all racing series

24h Le Mans, FIA WEC, European Le Mans Series, 24h Spa-Franchorchamps, 24h Nürburgring, Blancpain-GT Series, IMSA Championships, Creventic 24h Series Middle East

Leading factory teams rely on illuminated start numbers from XTRA Dynamics in racing.

We produce and supply start number lighting including electronics (EL inverter).

Our EL foils and EL inverters are used in GT and LMP racing. They are characterized by vibration resistance, low weight and extreme operational reliability.

Advantages of our EL car numbers:

• in the dimensions of all organizers

• very thin

• vibration resistant

• robust protection

• Flat ribbon connection

• incl. cable and plug connector

• extreme reliability

Frequently asked questions

The discovery of the electroluminescence effect is attributed to George Destriau, who discovered in 1936 in Mdm. Curie's laboratory in Paris in 1936 that a material (zinc sulphide contaminated with copper) created by an error during the burning process reacted to high electric fields by emitting light. His work in the following years formed the basis for the development of modern EL films.

When an electric current flows through certain materials, electrons in these materials can be raised to a higher energy level. When these electrons return to a lower energy level, light is emitted in the form of photons. This light emission process is known as electroluminescence.

When an alternating voltage is applied to the electrodes, this excites the electroluminescence in the film, which leads to a uniform emission of light over the entire surface.

An LED (Light Emitting Diode) is also a semiconductor component that emits light when an electric current flows through it. The process underlying this light emission is also known as electroluminescence. In contrast to an EL foil, an LED requires a DC voltage.

-

EL films can be used wherever their unique properties are required.

- Flexible: EL films are bendable and can be bent into various shapes. This makes them ideal for applications where flexible light sources are required.

- Thin: The films are thin and light, which makes them particularly suitable for applications where low weight and thickness are important.

- Uniform: EL foils are so-called Lambertian emitters, so they produce a uniform light emissions over their surface, which makes them glare-free and pleasant to look at.

- Customizable: By using different phosphors, EL films can shine in different colors, making them versatile. Typical applications for EL foils are backlighting for displays, keyboards, advertising materials and speedometers.